Stop Plastic. Start Plastilose.

Every year, 30+ million plastic medication cups end up in incinerators. We make the first 100% plastic-free, PFAS-free medication cup that naturally biodegrades within 3 months — even if you throw it in the forest.

The Problem with Medication Cups

Healthcare institutions use tens of millions of plastic medication cups annually. All for single use. All destined for incineration. And while paper alternatives often seem better, they're frequently even worse.

30+ Million per Year

In hospitals and healthcare institutions alone, more than 30 million plastic medication cups are thrown away annually. That's 82,000 cups per day.

95% of Paper Cups Contain PFAS

"Sustainable" paper cups almost always contain plastic coating AND PFAS — forever chemicals that accumulate in the body and don't break down in the environment.

Microplastics in Patients

Every plastic cup contributes to microplastics. Recent research shows: microplastics are now measurable in human blood. Healthcare must become part of the solution.

We're Building the Solution

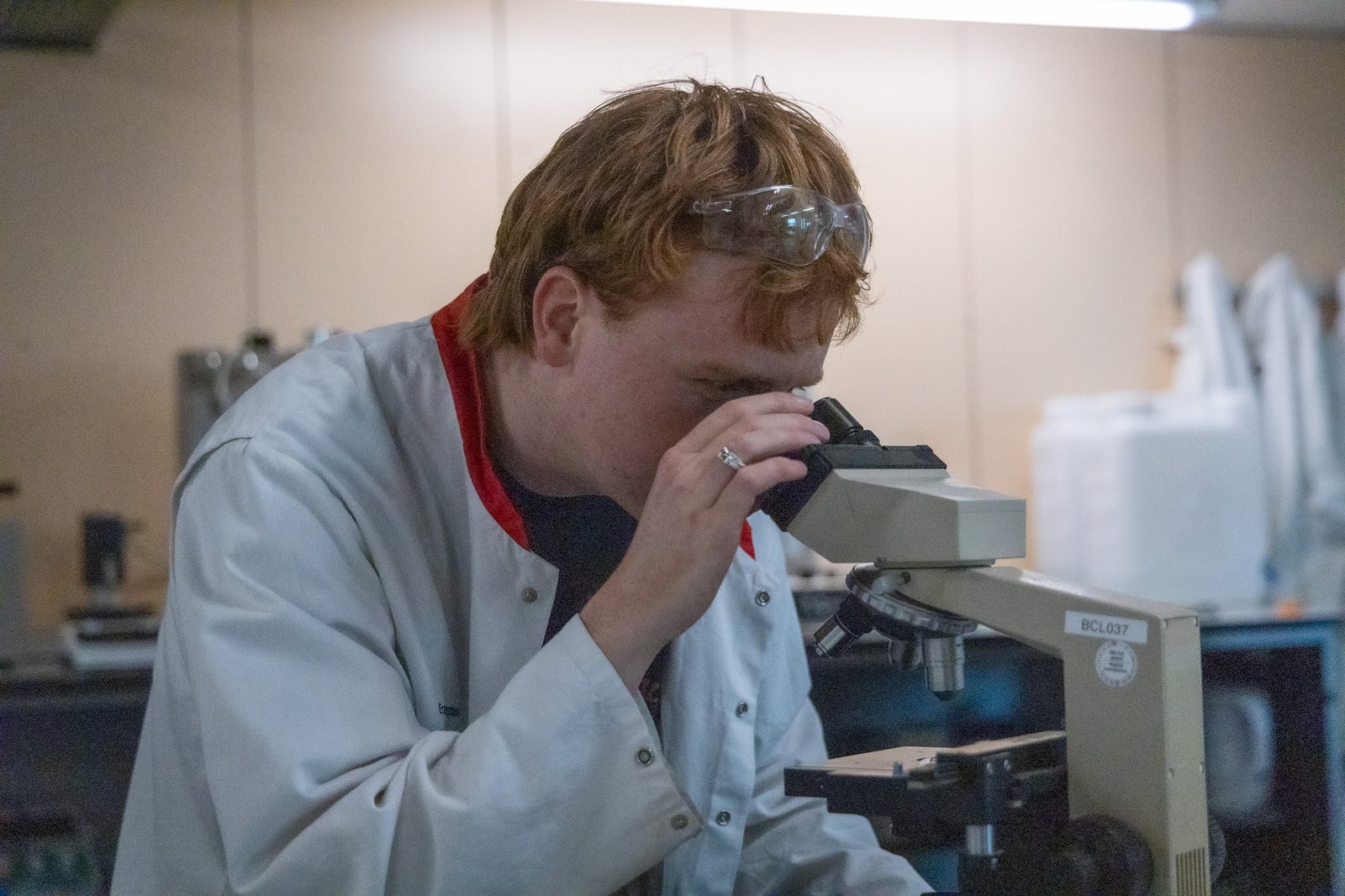

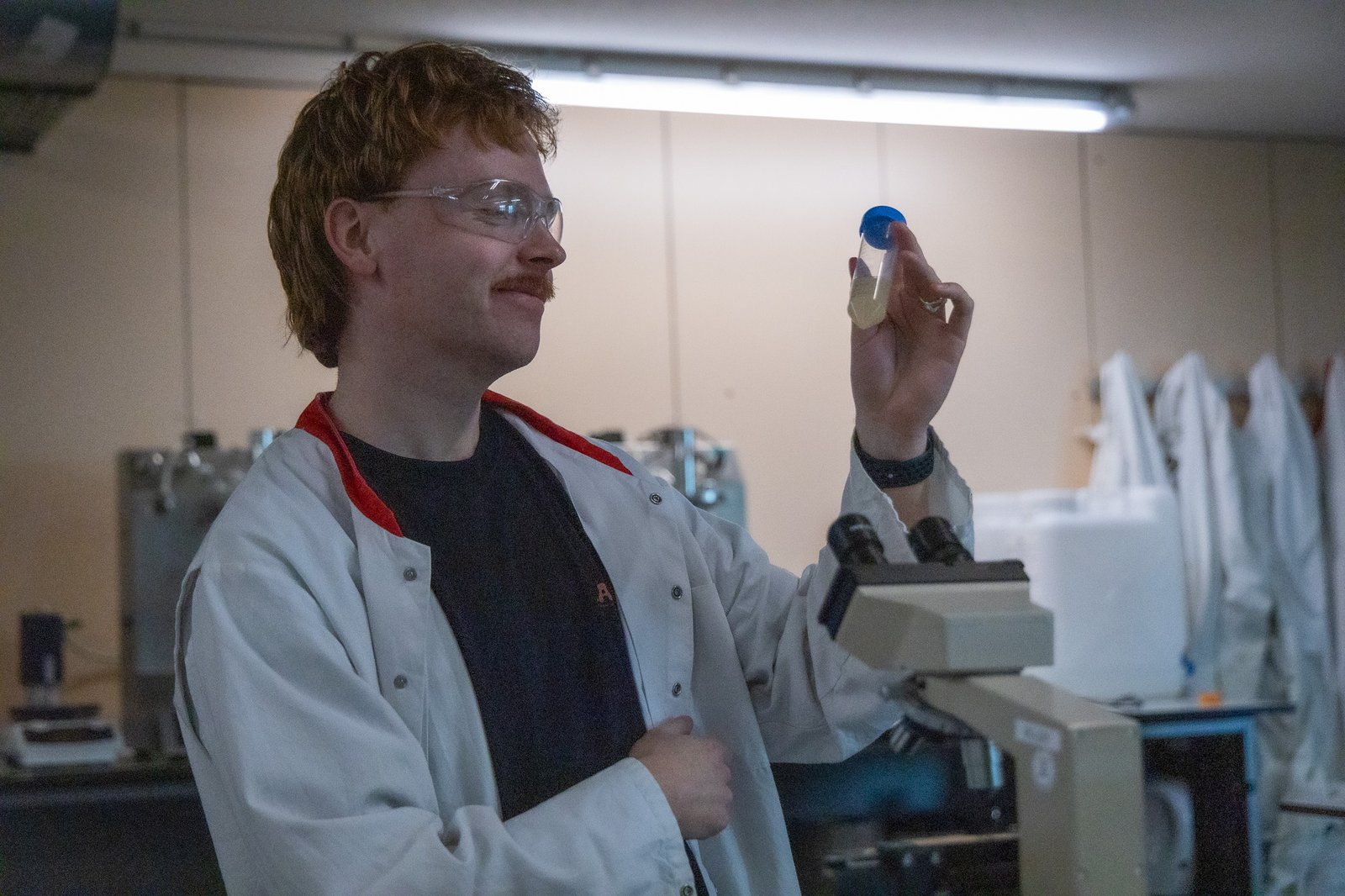

Rotterdam mentality, Delft expertise. We are Joram and Jason. Started at BlueCity Rotterdam, now producing at Biotech Campus Delft.

Our material: bacterial cellulose. A natural biopolymer grown by micro-organisms from waste streams of the Dutch sugar industry. It feels like plastic, but is 100% natural.

The key difference? Throw our cup in the forest, in a ditch, or in any waste bin — after 3 months it's completely gone. No microplastics, no PFAS, no toxins.

We're not a multinational. We're a startup that believes real change starts with honest products. That's why we openly share the science behind our material.

"Het voelt als plastic, maar is duurzaam"

— Read our story in the AD (Dutch newspaper)Our Medication Cup

A medication cup that's just as functional as plastic, but without the environmental impact. Developed for healthcare, tested for safety and sustainability.

Bacterial Cellulose

Chemically identical to plant cellulose, but >99% pure. No lignin, no hemicellulose, no contaminants.

Stronger than PP Plastic

Tensile strength up to 200 MPa. Ideal for daily use in healthcare and compatible with pill crushers.

Liquid Resistant

Hydrophilic surface ensures minimal medication adhesion. Liquid medications drain completely.

Guaranteed PFAS-Free

No forever chemicals, no plasticizers, no microplastics. Safe for direct medication contact.

Naturally Biodegradable

Throw it in nature, in water, or in any waste bin — fully decomposed within 3 months. No toxic residues, no microplastics.

Scientifically Proven Safe

Our material has been extensively studied by independent scientists worldwide. Below are the key findings from peer-reviewed research.

Chemical Purity

Bacterial cellulose contains no extractable contaminants. The crystallinity of 84-93% ensures a stable molecular structure.

Chemical Reactions with Medication

FTIR spectroscopy shows: no shift in carbonyl frequency, no new peaks indicating chemical bonding. "No chemical interaction" — Jantarat et al. (2021)

FDA Status

Bacterial cellulose is recognized as "Generally Recognized as Safe" by the FDA for food contact. Multiple BC wound dressings are already on the market as medical devices.

Biocompatibility

Tested according to ISO 10993 standards. Studies show: non-cytotoxic, no inflammatory response, no foreign body response. NOAEL >5,000 mg/kg body weight/day.

Sterilizable

Compatible with autoclave (121°C), gamma radiation (25 kGy), and ethylene oxide. Structure and properties are preserved after sterilization.

Natural Decomposition

Completely and naturally biodegrades in nature, in water, or in soil — within 3 months. No special processing needed. Can go in any waste stream without environmental impact.

Honest Comparison

| Property | Plastilose | Plastic (PP) | Paper |

|---|---|---|---|

| 100% Plastic-Free | ✓ | ✗ | ✗ (coating) |

| PFAS-Free | ✓ | ✗ | ✗ (95%!) |

| Naturally Biodegradable | ✓ 3 mo | ✗ centuries | ✗ coating |

| No Microplastics | ✓ | ✗ | ✗ |

| Medication-Safe | ✓ proven | ✓ | ± |

| Sterilizable | ✓ all methods | ± limited | ✗ |

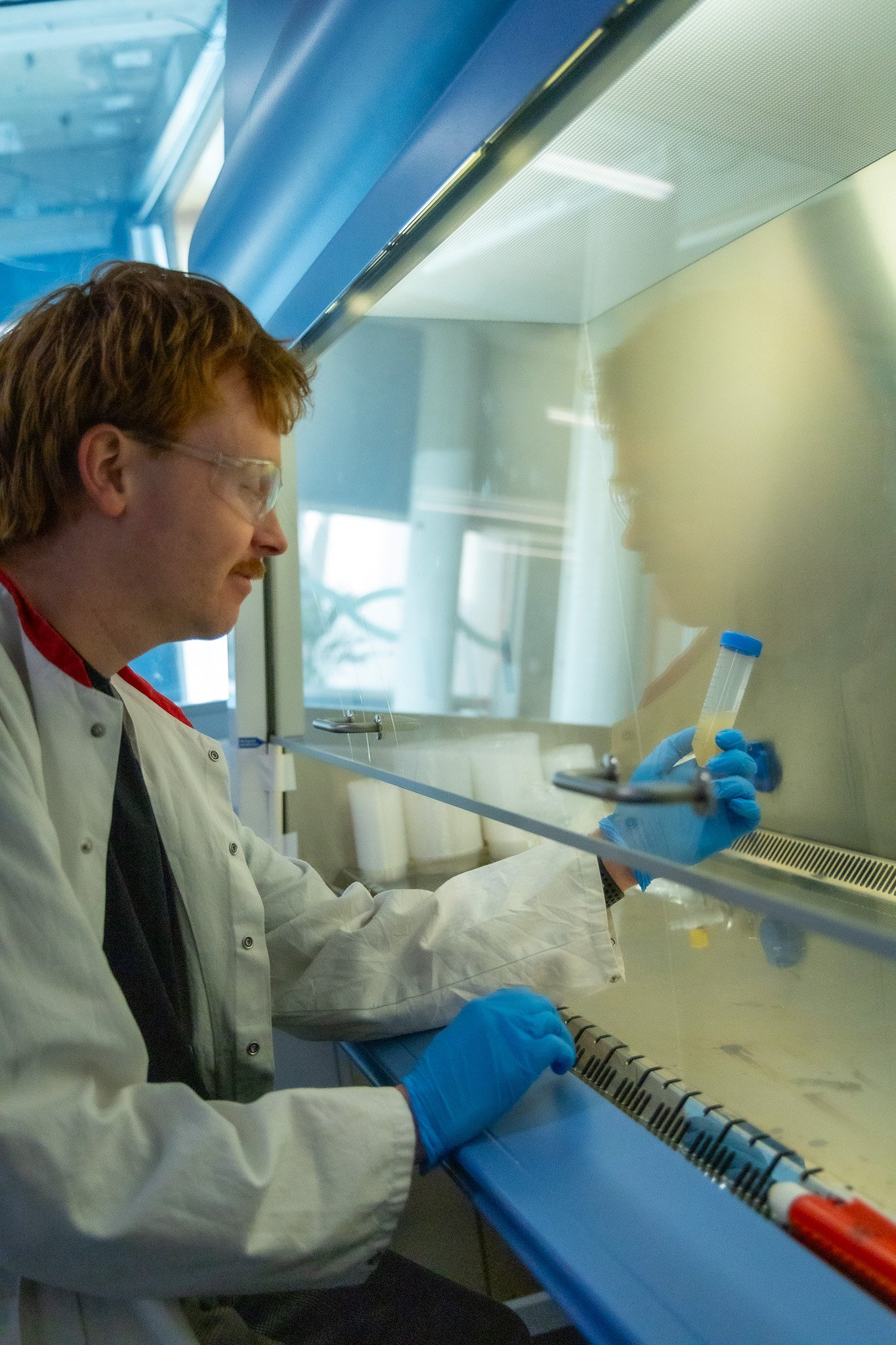

From Waste Stream to Medication Cup

Our circular production process at Biotech Campus Delft.

Fermentation

In static bioreactors, selected micro-organisms convert sugar-rich waste streams from the Dutch sugar industry into pure bacterial cellulose. Static fermentation yields a crystallinity of 84-93%.

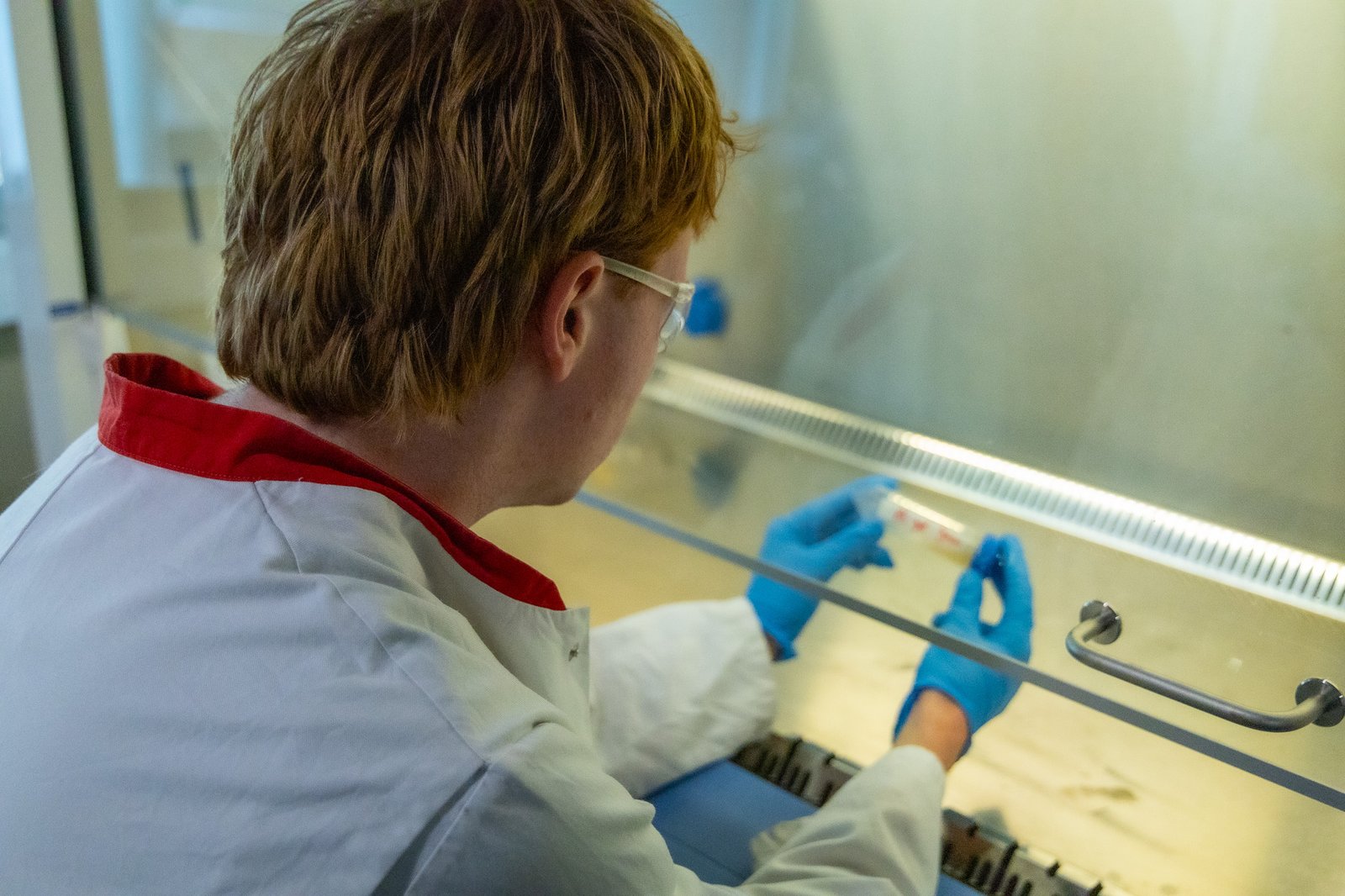

Purification

The formed cellulose is washed and purified. What remains is a nanofiber network with >99% purity — completely natural and suitable for medical use.

Shaping

The cellulose is pressed and shaped into stable medication cups. The strong nanofiber network (Young's modulus 428 ± 24 MPa) maintains form and rigidity, even when in contact with liquids.

Real Impact, No Greenwashing

Concrete numbers about what switching means — and why it doesn't matter which bin the cup ends up in.

Less CO2 emissions

Microplastics

PFAS exposure

Decomposition time in nature

Works With Any Waste Stream

In a busy healthcare environment, it's impossible to put every cup in the right bin. With Plastilose it doesn't matter — anywhere is better than plastic.

Frequently Asked Questions

Co-Creation with Healthcare

Multiple hospitals and healthcare institutions have already shown interest. Together we're developing a product that solves problems, not creates them.

Developed with healthcare staff

We believe that real innovation comes through collaboration. That's why we develop our medication cups not in an ivory tower, but together with the people who use them daily.

We work with multiple healthcare institutions to ensure our product has minimal impact on staff workload. A sustainable cup that's harder to use is no solution.

Co-creation with healthcare staff

Nurses and pharmacists contribute to shape, grip, and ease of use

No new problems

Our cup must seamlessly fit into existing workflows

Honest about the development phase

We're a startup in development — together we make it better

Calculate Your Impact

Discover how much plastic, CO2, and microplastics your institution can save by switching to Plastilose medication cups.

Curious about the specific impact for your institution?

Request a QuoteScientific Foundation

All claims are based on peer-reviewed research. 15 sources in APA style.

View all 15 scientific sources

Safety & Biocompatibility

- Girard, V.-D., Chausse, J., Borduas, M., Dubuc, E., Iorio-Morin, C., Brisebois, S., & Vermette, P. (2024). In vitro and in vivo biocompatibility of bacterial cellulose. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 112(10), e35488. https://doi.org/10.1002/jbm.b.35488

- Hagiwara, A., Doi, Y., Tamano, S., Omoto, T., Asai, I., Yasuhara, K., & Hayashi, S. (2010). A 28-day oral toxicity study of fermentation-derived cellulose, produced by Acetobacter aceti subspecies xylinum, in F344 rats. Journal of Toxicological Sciences, 35(3), 317-325. https://doi.org/10.2131/jts.35.317

- Costa, A. F. S., Almeida, F. C. G., Vinhas, G. M., & Sarubbo, L. A. (2017). A review on the toxicology and dietetic role of bacterial cellulose. Toxicology Reports, 4, 566-571. https://doi.org/10.1016/j.toxrep.2017.11.002

Drug Interaction & Drug Delivery

- Jantarat, C., Muenraya, P., Srivaro, S., Nawakitrangsan, A., & Promsornpason, K. (2021). Comparison of drug release behavior of bacterial cellulose loaded with ibuprofen and propranolol hydrochloride. RSC Advances, 11(60), 37354-37365. https://doi.org/10.1039/D1RA07761A

- Ullah, H., Santos, H. A., & Khan, T. (2016). Applications of bacterial cellulose in food, cosmetics and drug delivery. Cellulose, 23(4), 2291-2314. https://doi.org/10.1007/s10570-016-0986-y

- Abeer, M. M., Mohd Amin, M. C. I., & Martin, C. (2014). A review of bacterial cellulose-based drug delivery systems: Their biochemistry, current approaches and future prospects. Journal of Pharmacy and Pharmacology, 66(8), 1047-1061. https://doi.org/10.1111/jphp.12234

Material Characterization & Mechanical Properties

- Skogberg, A., Maki, A.-J., Mettanen, M., Lahtinen, P., & Kallio, P. (2017). Cellulose nanofiber alignment using evaporation-induced droplet-casting, and cell alignment on aligned nanocellulose surfaces. Biomacromolecules, 18(12), 3936-3953. https://doi.org/10.1021/acs.biomac.7b00963

- Gao, M., Li, J., Bao, Z., Hu, M., Nian, R., Feng, D., ... & Zhang, H. (2019). A natural in situ fabrication method of functional bacterial cellulose using a microorganism. Nature Communications, 10(1), 437. https://doi.org/10.1038/s41467-018-07879-3

- Park, S., Baker, J. O., Himmel, M. E., Parilla, P. A., & Johnson, D. K. (2010). Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnology for Biofuels, 3, 10. https://doi.org/10.1186/1754-6834-3-10

Biodegradability & Environmental Impact

- Picheth, G. F., Pirich, C. L., Sierakowski, M. R., Woehl, M. A., Sakakibara, C. N., de Souza, C. F., ... & de Freitas, R. A. (2017). Bacterial cellulose in biomedical applications: A review. International Journal of Biological Macromolecules, 104(Pt A), 97-106. https://doi.org/10.1016/j.ijbiomac.2017.05.171

- Abol-Fotouh, D., Hassan, M. A., Shokber, H., Roig, A., Azab, M. S., & Kashyout, A. E.-H. B. (2020). Bacterial cellulose: Sustainable and cost-effective material for industrial biotechnology applications. Cellulose, 27(18), 10465-10491. https://doi.org/10.1007/s10570-020-03307-8

- Sathish, S., Supriya, V., & Balaji, D. (2023). Biodegradability of bacterial cellulose polymer below the soil and its effects on soil bacteria diversity. Polymer Degradation and Stability, 216, 110496. https://doi.org/10.1016/j.polymdegradstab.2023.110496

Medical Devices & FDA Status

- Czaja, W. K., Young, D. J., Kawecki, M., & Brown, R. M. (2007). The future prospects of microbial cellulose in biomedical applications. Biomacromolecules, 8(1), 1-12. https://doi.org/10.1021/bm060620d

- Meslier, A., et al. (2025). A comprehensive review of clinical studies on bacterial cellulose: From the earliest uses to contemporary innovations. Advanced Healthcare Materials. https://doi.org/10.1002/adhm.202502189

- U.S. Food and Drug Administration. (2003). 510(k) Premarket Notification: XYLOSTM XCell Antimicrobial Dressing (K024054). FDA Database

Sterilization & Stability

- Stumpf, T. R., Yang, X., Zhang, J., & Cao, X. (2018). In situ and ex situ modifications of bacterial cellulose for applications in tissue engineering. Materials Science and Engineering: C, 82, 372-383. https://doi.org/10.1016/j.msec.2016.11.121

- Rebelo, A. R., Archer, A. J., Chen, X., Liu, C., Yang, G., & Liu, Y. (2018). Dehydration of bacterial cellulose and the water content effects on its viscoelastic and electrochemical properties. Science and Technology of Advanced Materials, 19(1), 203-211. https://doi.org/10.1080/14686996.2018.1430981

Note: This reference list is not exhaustive. For additional scientific documentation, please contact us.